September 16 – 28

Arriving in downtown Louisville, we parked a couple of blocks away from the Louisville Slugger Museum and Factory an attraction that showcases the story of Louisville Slugger baseball bats in baseball and in American history. The facility is the fourth location where Louisville Slugger bats have been made, with the original shop on South First Street in Louisville between Main and Market Streets. It was there that family legend suggests J. A. “Bud” Hillerich made a bat for Louisville Eclipse star Pete Browning after Browning broke his bat during a game in which Hillerich attended in July 1884. The next day, Browning got three hits with the bat and the legend was born.

From 1974 to 1996, Louisville Sluggers were made in Jeffersonville, Indiana, just across the Ohio River at a facility called Slugger Park, while H&B maintained corporate offices on Broadway in Louisville. Starting in the early 1990s, CEO John A. “Jack” Hillerich III began looking to move production back to Louisville as he wanted to bring the factory back together with the business offices while also providing a place for the public to connect with the Louisville Slugger brand.

The building also houses corporate offices for Hillerich & Bradsby and its two other divisions, Bionic Gloves and PowerBilt Golf Clubs. Wilson Sporting Goods maintains much of its Louisville Slugger sales force in the building after purchasing the brand from Hillerich & Bradsby in 2015. The Hillerich family maintains ownership of the museum and bat factory. In 2013, the Museum & Factory broke its own attendance record, drawing more than 303,000 visitors.

Attractions one can visit inside the complex are:

World’s Largest Baseball Bat – Guinness World Records for largest baseball bat is 120 ft. tall. and weighs 68,000 pounds.

Signature Wall – Giant wooden wall in foyer displaying signatures of every Louisville Slugger contract player.

Museum Gallery – Variety of interpretive and interactive exhibits.

Factory Tour – Tour of the world-famous Louisville Slugger bat factory.

Bat Vault – Guest look into room where all Louisville Slugger bat models are kept and are allowed to hold select replica models.

Batting Cages – Guests can use historic bat models or the latest Louisville Slugger composite models to swing for the fences.

Museum Store – Gift store featuring Louisville Slugger items, historic memorabilia from Hunt Auctions and personalized bats.

One enters the building near the gift shop and after purchasing the entry fee, is directed to the museum which features the History of the Bat where guests learn about the making of the first Louisville Slugger bat. Also, on exhibit are:

Hold a Piece of History where one can hold a game-used bat from one of many hall of fame players, Players Choice which displays models of bats used by current players, a statue gallery of famous major leaguers,

Feel the Heat where guests see what it’s like to face a 90 MPH fastball and watch docents demonstrate how the bats are burned with the signature of current players,

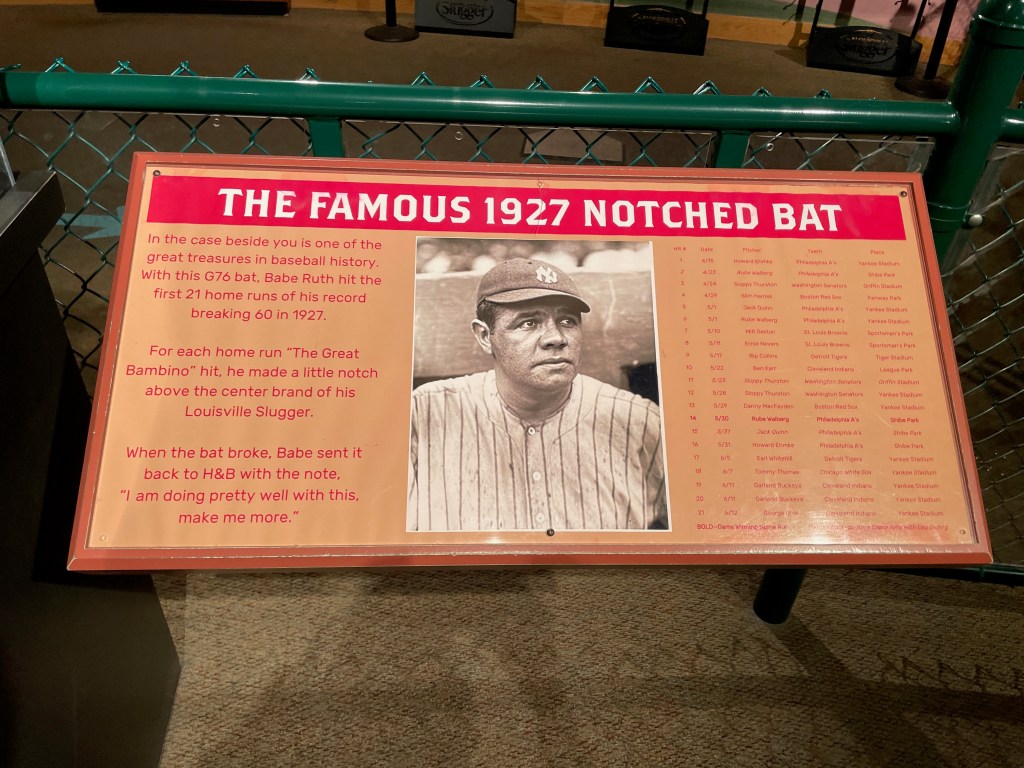

And Babe Ruth’s famous notched bat, a replica of the one he used in 1927. It measures 35 ¾ inches and weighs approximately 38 ounces and has 28 notches around the Louisville Slugger brand above the bat’s handle. The Babe began carving small notches on his bats for each home run in the second half of the ’27 season. An original bat resides at baseball’s Hall of Fame in Cooperstown, New York where it is labeled: “Each notch on this War Club of the Babe’s represents one Apple knocked out of the Ball Orchard.”

We then began our tour of the bat factory, which consists of five stops showing how the famous bats are made. The first station is the holding area for the Northern white ash and maple billets that get turned into bats. Next up is the automatic tracer lathe, which takes about 40 seconds to make a bat. Workers use a metal pattern of the exact bat shape and guide the machine to trace this pattern, a process like copying a key at the hardware store. All the Major League bats are made on a special CNC lathe, the only one of its kind in the world.

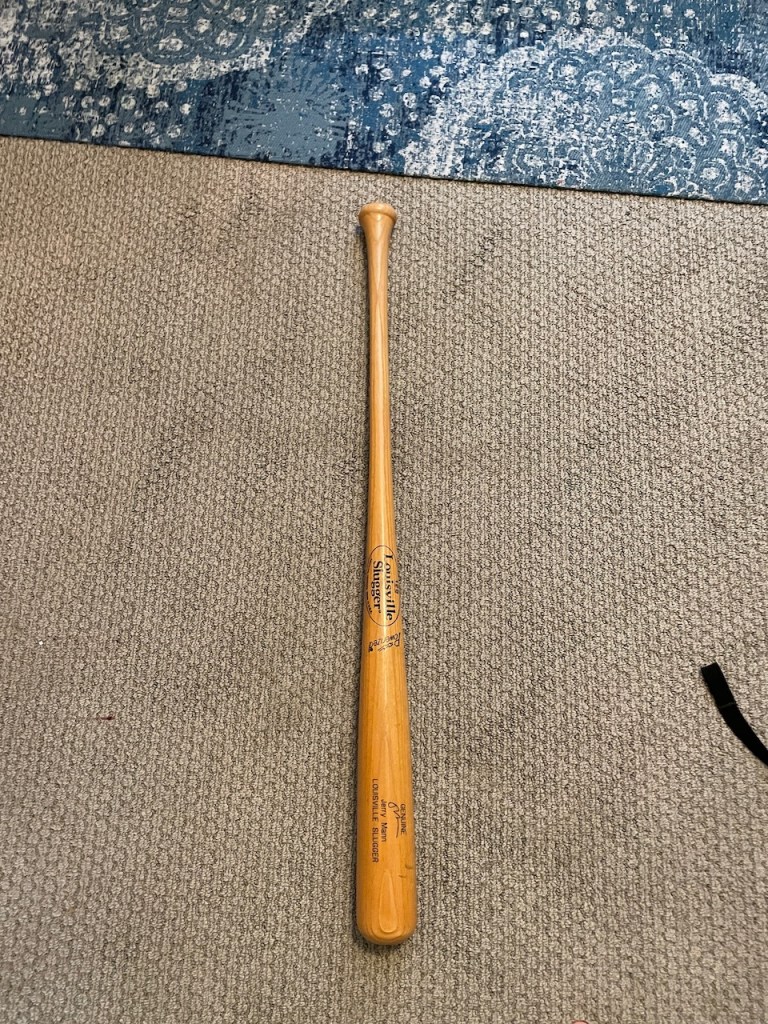

A dedicated machine then lops off the wood tags on each end of the bat that are there to hold it in the lathe. Next, the famous oval trademark, bat model number, and the player’s autograph are seared into the “flat of the grain” on some bats. Bats can also be foil-branded with either gold or silver. Behind the branders are large cabinets holding more than 8,500 professional baseball players’ autograph brands.

Finally, the bats head to the staining station where the finish is applied, and the bats are inspected before being released for use or sale. We hit the gift shop and I recalled my last visit here when my sister Bev bought me my own autographed bat, which I proudly hang in our office/spare bedroom at the house.

In anticipation of our touring the Evan Williams Bourbon Experience at 1:30, Doug opted to miss the tour and have lunch with one of his relatives who works downtown. To kill time the rest of us hit a Starbuck’s a couple of blocks away, a welcome break from the alcohol-heavy routine we’d been perfecting. Often, it’s in these quiet moments that good friends have the best conversations, no distractions to get in the way of sharing information we’d been holding back for just the right moment to reveal itself. No life-or-death topics here, just those heartfelt sentiments that true friends share.

Links

Louisville Slugger Museum and Factory: https://www.sluggermuseum.com/

Evan Williams Bourbon Experience: https://evanwilliams.com/plan-your-trip

Discover more from 3jmann

Subscribe to get the latest posts sent to your email.